|

|

|

|

|

|

|

|

>

INTERNATIONAL ECOCITY CONFERENCE in

Shenzhen, China > WASTE & TRAFFIC MANAGEMENT: PRESENTATIONS AND VISITS in Cologne, Germany |

||||

| The 5th International Ecocity Conference, Shenzhen, China 19-23 August 2002 By Lalit Kishor Bhati, Urban Planner, Auroville's Future, Auroville |

|||||

|

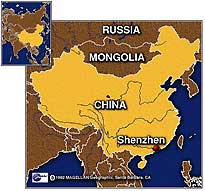

The conference took place on August 19-23, 2002 in Shenzhen, the fastest developing city in China. The main subject of the conference was "New Millennium, New City". The Symposium constituted a major milestone of the eco-city in the world. In addition, six symposiums were held. |

||||

|

|

||||

|

ORGANIZED BY:

|

|||||

|

SUPPORTEDD BY: |

||||

|

|||||

| The related website addresses are

as following - Home page - http://www.ias.unu.edu/proceedings/icibs/ecocity03/ Lalit's Paper Abstract - http://www.ias.unu.edu/proceedings/icibs/ecocity03/papers/bhati/index.html Lalit'sfullwrittenPaper- http://www.ias.unu.edu/proceedings/icibs/ecocity03/papers/bhati/paper.html Lalit's Power Point Presentation (96 slides) http://www.ias.unu.edu/proceedings/icibs/ecocity03/papers/bhati/ppt.html |

|||||

WASTE & TRAFFIC MANAGEMENT presentations & visit in Cologne, Germany |

|||||

| 16th - 22nd Dec. 2002 By Dr. Lucas, in charge of the solid waste mangement unit in Auroville Facilitated by the Municipality of Cologne - Germany |

|||||

Tuesday, December 17th Visit to paper recycling plant Accompanied by Mr. Gosciniak & Mrs. Stüwe of Commission Health and Environment. |

|||||

|

This plant owned to larger part by RWE (multi-utility company,

large enterprise in energy sector, biggest company in Germany dealing with

SWM, running about 500 sites in Germany, dealing with 800 types of waste)

processes paper waste of one million people (Cologne), 60 tons of waste

paper per year; produces three grades for further re-use / recycling: grade

for de-inking and newsprint paper, cardboard, toilet and tissue paper; employs

21 - 25 people; consists of one X-ray check to sort out metals and other

unwanted large-bulk waste; six people per shift, everybody skilled in all

tasks to reduce exposure to monotonous jobs, sharing duties such as hand-picking

of waste, cleaning and repair of machinery, organizing their own work. Investment costs into machinery were 3 Mill. EURO. Presently, incineration per ton waste costs 211 EURO, disposal on a dumpsite costs 150 EURO per ton. The participants received information on the dual system of German waste

and waste packaging management, and on 'Gruener Punkt System' and an insight

into the strongly-disputed system which relies heavily on transport of

waste, and generates a lot of "residual waste" for incineration.

|

||||

|

|||||

Visit to refrigerator recycling, aluminum recycling and battery recycling plants The battery recycling plant was a sorting plant only with recycling is being done by manufacturers who are obliged to take back discarded batteries and to retrieve heavy metals from them (and/or pay for hazardous waste disposal). Costs are built into prices of products. Impressions of visitors from India - Impressive technical performance, extraordinary cleanliness, management streamlined. Investment costs into machinery enormous, labour intensity extremely reduced by employment of machinery. |

|||||

|

|||||

Wednesday, December 18th The participants were introduced into twenty different European laws on Solid Waste Management (SWM) and on system of municipal SWM, involvement of private companies etc. Knowledge of law in general was lacking, not only for general public, but also for entrepreneurs; knowledge and information on waste reduction and waste re-use was also lacking. |

|||||

Visit to waste transfer station at Rath-Heumar Here waste collecting vehicles unload mixed 'residual' municipal waste. The waste was compressed and put onto a rail into the incineration plant. Logistic system has been developed since more than fifteen years, in consideration of site availability, traffic loads and economics. |

|||||

|

Visit to Waste incinerator plant The Plant has been running since February 1998 after a period of construction two years. Investment costs 800 Mill. DM for incinerator, totally 1,200 Mill. DM for complete plant including administrative buildings and composting plant. 130 Mill. DM were spent on pre-sorting plant i.e. sorting out metals and homogenization of waste for uniformity of characteristics, in particular of calorific value of waste. One-third of investments were for emission control and monitoring. The plant was in regard to emissions one of the best performing in Europe and the world, the levels much below permissible levels, continuous on-line monitoring of all major parameters; dioxins and furans checked quarterly by independent lab, far below permissible level, i.e. in ppb range. Four incineration plants ran parallely. In case of failure, three-quarters of capacity remained operating. The plant processed 650,000 tons per year, of which 400,000 tons are from Cologne city, and the rest from the surrounding region. The company also ran a dumpsite operating in the region, which would have to be shut down by 2003/04, and would be allowed to receive inert material only. Impression of the workshop participants: The technical performance seemed to be the world's best, possible through enormous investment and maintenance costs. Such a project could be financed only by large companies and high contributions from each customer which in this case is the citizen. Technical requirement for consistent high energy output is pre-sorting and homogenization. |

||||

Thursday, December 19th |

|||||

| Visit to technical complex of municipality departments (Cologne Arena). Accompanied by Mr. Deistler | |||||

| The visit was to the traffic management centre, developed

by Cologne municipality (software) and Siemens (hardware). With the help

of twenty screens from video cameras positioned in various crucial traffic

nodes, a person monitors all traffic information and sends out messages

via signboards and radio and TV video text; for the sake of data protection,

no other use allowed with the system (no zooming into windows, onto car

registration plates etc.) All pictures accessible via internet to the public!

Impact on traffic was measured and is regarded as significant. Mr. Deistler later gave another overview of history and development of Cologne, with the help of maps; then an introduction into city administration in general, its history, its present status in Germany. |

|||||

|

The Lord Mayor is elected by the people heads' administration ('the executive'); the administration consists of nine departments under nine commissioners plus nine heads elected by the city council. European office headed by Mr. Deistler falls under Commission of Lord Mayor; other commissions are as follows: City Director, Finances, Taxes, Real Estate; Health and Environment; Schools and Education; Youth. Sports, Aged, Social; Construction and Transport; Culture; Economic Urban Development; Green Areas and District. A Call Office deals with 70% of all citizens' applications. Long-term development planning (over twenty to twenty-five years) is being done on the conceptual level; legally binding planning is done patch-wise as projects and regions require actual planning. |

||||

Visit to tunnel underneath river Rhine The tunnel was built in the eighties by a private company to bring heat (vector water) from one side of the Rhine to the other. Bridges could not be used, either for legal reasons (German Railway) or for technical reasons. The Rhine bed could not be used for legal reasons (international water traffic). The participants then gained some insight into German / European energy market. |

|||||

|

|||||

Friday, December 20th Visit to Eigelstein-Gate, medieval building utilized by citizens |

|||||

| This visit included a walk through a particular sector of inner city, visiting municipality-supported projects of city renewal. The participants observed how architectural designs of different times and completely different styles co-existed next to each other. | |||||

| LIST OF PARTICIPANTS 1. Mr. Gurumurthi - Chief Town Planner, Tamil Nadu Government, Chennai |